2022 James Dyson Award Global Winners Announced

16 November 2022INTERNATIONAL WINNER

SmartHEAL, A smart sensor for dressings which indicates how well a wound is healing by measuring its pH level, invented by students from Warsaw University of Technology, Poland.

SUSTAINABILITY WINNER

Polyformer, A machine that recycles plastic bottles into affordable 3D printer filament for developing nations, invented by students from McMaster University, Canada.

INTERNATIONAL RUNNER-UP

Ivvy, A wearable replacement for the existing intravenous drip pole apparatus, improving comfort and mobility for patients, invented by Charlotte Blancke from the University of Antwerp, Belgium.

The James Dyson Award has given more than £1m in prize money to over 300 promising inventions from young engineers and scientists around the world. This year, Sir James Dyson has selected two global winners, each receiving £30,000, and one runner-up, receiving £5,000 in prize money, to support the next stages of their inventions.

"Every year, the James Dyson Award offers proof that young people are passionate about improving the planet and solving environmental and medical problems. There are people who grandstand over the issues they care about, but these young inventors are doing something more productive. They are diligently applying themselves to problem-solving using engineering, science and ingenious design."

Sir James Dyson, Founder and Chief Engineer at Dyson.

-

Invented by Tomasz Raczyński, Dominik Baraniecki and Piotr Walter Warsaw University of Technology, Poland

-

International winner – SmartHEAL

The problem

When covered by a dressing, it is very hard to know how well a wound is healing. The most common mistake in wound healing is changing the dressing too often, which can lead to infections and tissue disruption1.

Current methods of assessing a wound rely on subjective scoring of colour, smell, temperature – or expensive laboratory biochemical tests2. Poor wound healing not only leads to tissue inflammation, but also necrosis (death of body tissue that is irreversible), and can lead to severe illness or death.

In Southeast Asia region, it is estimated that the proportion of elderly people aged 60 and above will increase from 9.8% to 20.3% by 20503. In 2021, there were just over 639 thousand residents aged 65 and above in Singapore4. Elder people face diverse health issues – one of them being a slower recovery process making chronic wounds a persistent problem in this population.

The solution

SmartHEAL is a precise, affordable and scalable smart pH sensor for dressings. By using Radio-Frequency Identification (RFID) communication systems and monitoring the pH of a wound, SmartHEAL can assess the wound’s condition and detect infection without removing the dressing, and therefore without disrupting the tissue5. Medical professionals can subsequently analyse the data and prescribe the appropriate treatment for the wound. Smart bandages create and preserve a balanced wound environment6.

Next steps

The team will finish testing and then start clinical trials. Their aim is to then finish the certification process in three years’ time so they can start to distribute and sell SmartHEAL dressings in 2025.

1https://www.cornerstoneuc.com/2021/04/23/side-effects-of-improper-wound-care/

2https://pubs.acs.org/doi/10.1021/acssensors.1c00552

3https://www.who.int/southeastasia/health-topics/ageing

4https://www.statista.com/statistics/1307632/singapore-number-of-elderly-residents/

5https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4486717/#:~:text=pH%20has%20a%20significant%20role,at%2Drisk%20or%20infected%20wounds.

6https://www.news-medical.net/health/How-Could-Smart-Bandages-Revolutionize-Wound-Care.aspx

-

Invented by Swaleh Owais and Reiten Cheng McMaster University, Canada

-

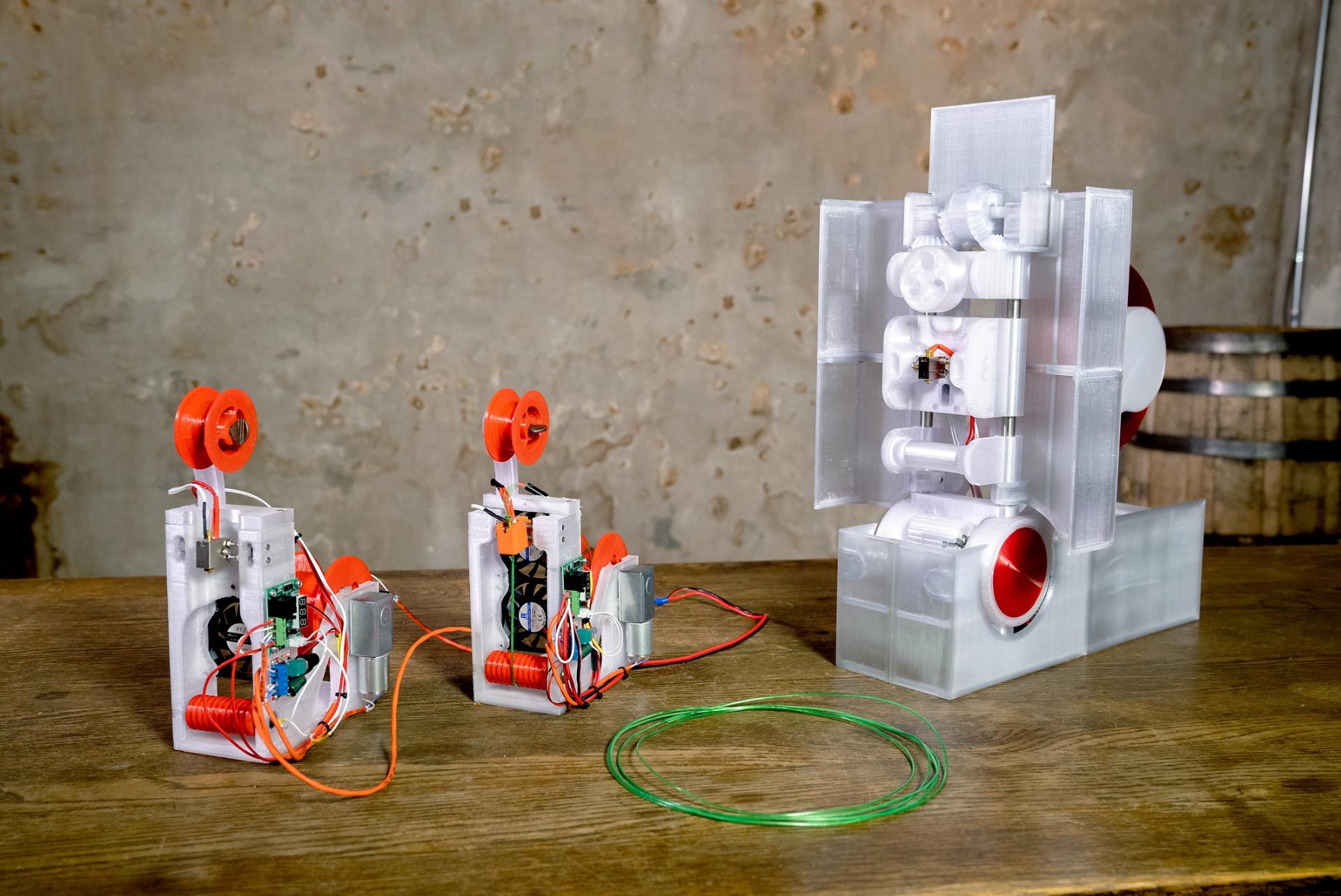

Sustainability winner – Polyformer

The problem

While working at a makerspace in Rwanda, Swaleh and Reiten learned that many locals could not use the makerspace's 3D printers, due to the high price of importing filament to the country1. They also observed the lack of infrastructure to recycle plastic bottles in Rwanda.

The solution

Polyformer is a low-cost machine that turns plastic bottles into 3D printer filament. Polyformer cuts plastic bottles into long strips that are fed into an extruder. The strip is then thermoformed into 1.75mm filament, as it goes through a nozzle. The filament is passed through vents to cool the plastic before it is wrapped around a spool, ready to be inserted into a 3D printer.

The invention is targeted at developing nations due to the high price of importing 3D printer filament. With Polyformer, makers have easier access to cheap, high-quality 3D printer filament. This encourages usage of design infrastructure and career consideration in developing nations, while empowering makers to recycle their own waste and use the output productively2.

Next steps

Currently, Swaleh and Reiten are building new Polyformers to deploy at their partner makerspaces in Rwanda and they are designing new inventions within the Polyformer project, such as the Polyjoiner, Polydryer, Polyspooler, and many more.

1https://www.ic3dprinters.com/trade-wars-and-tariffs-a-3d-printing-perspective/

2https://www.forbes.com/sites/richarddaveni/2019/03/19/how-3d-printing-can-jumpstart-developing-economies/

-

Invented by Charlotte Blancke University of Antwerp, Belgium

-

International Runner-up – Ivvy

The problem

Charlotte became aware that a colleague of her mother was unhappy about the uncomfortable apparatus her child was required to use for her medical treatment. The colleague mentioned that she in fact switched an intravenous pole for a coat hanger to improve her daughter’s comfort.

During Charlotte’s research, she found that at-home medical treatment is rising, but the equipment used for at-home intravenous therapies is the same as that in hospitals, despite the characteristics of a home setting being different. As more patients move to home healthcare services for recuperation or long-term care, complex medical devices are now used more frequently in the home, often under unsuitable conditions1.

The solution

Infusion therapy is when fluids or medication are administered through a cannula or needle at a controlled pace2. Ivvy replaces the current intravenous drip pole with a wearable device that provides patients with optimal mobility, an easy-to-use infusion pump, and on-board software so nurses can monitor their patients remotely.

Currently, there is a lack of feedback about intravenous treatments and existing infusion pumps have a complex interface. Charlotte has developed an infusion pump with a simplified interface and intuitive use. Nurses can easily set up the treatment at-home and patients can follow their therapy through a LED strip, display, and sound notifications.

Next steps

Charlotte is working with professionals in the industry to support her with further developing Ivvy.

1https://www.fda.gov/medical-devices/home-health-and-consumer-devices/home-use-devices

2https://www.healthline.com/health/infusion-therapy

The James Dyson Award forms part of a wider commitment by Sir James Dyson, to demonstrate the power of engineers to change the world. The competition has supported over 300 inventions with prize money, and is run by the James Dyson Foundation, an engineering-education charity funded by Dyson profits.

The Dyson Institute of Engineering and Technology and the Foundation’s work encourage aspiring engineers and problem solvers, to apply their knowledge and discover new ways to improve lives through technology. To date, James and the James Dyson Foundation have contributed over £140m to boundary breaking concepts in education and other charitable causes.

Heidy Tang

Email: heidy.tang@dyson.com