Prototyping Labs

Prototyping is the heart of successful product design, allowing technologies to be developed iteratively until they are as close to perfect as possible. They are used across all the stages of the design process, to quickly get a feel for things, uncover subtle design flaws and allow for rigorous testing.

When James Dyson first developed the DC01, he made all 5,127 iterations by hand. Today, the prototyping lab plays a crucial role in speeding up the process of new technologies. It is home to numerous machines, each one suited for different prototyping needs.

At Dyson, a team of 60 engineers spread across the UK, Singapore, Malaysia, and Philippines work on the prototyping team, working alongside design and manufacturing engineers to support the development and release of new products.

-

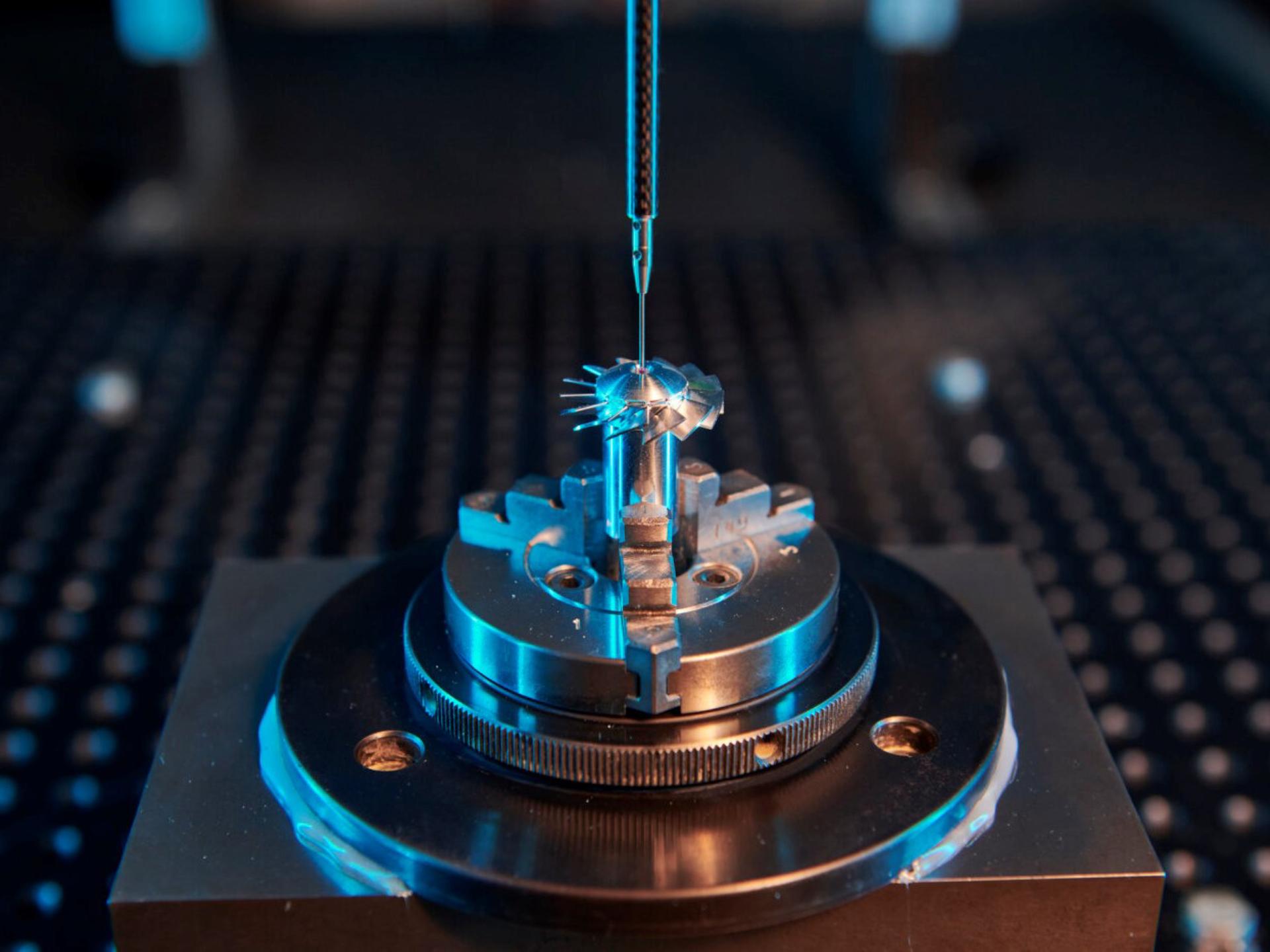

Electrical Discharge Machining (EDM)

EDM is an electro thermal manufacturing process. Metal is cut using electrical discharges from a single metal wire or electrode. The creates a spark and extremely high temperatures between 8,000 to 12,000oC, so the process takes place in deionized water which acts as a coolant and flushes away any eroded material.

-

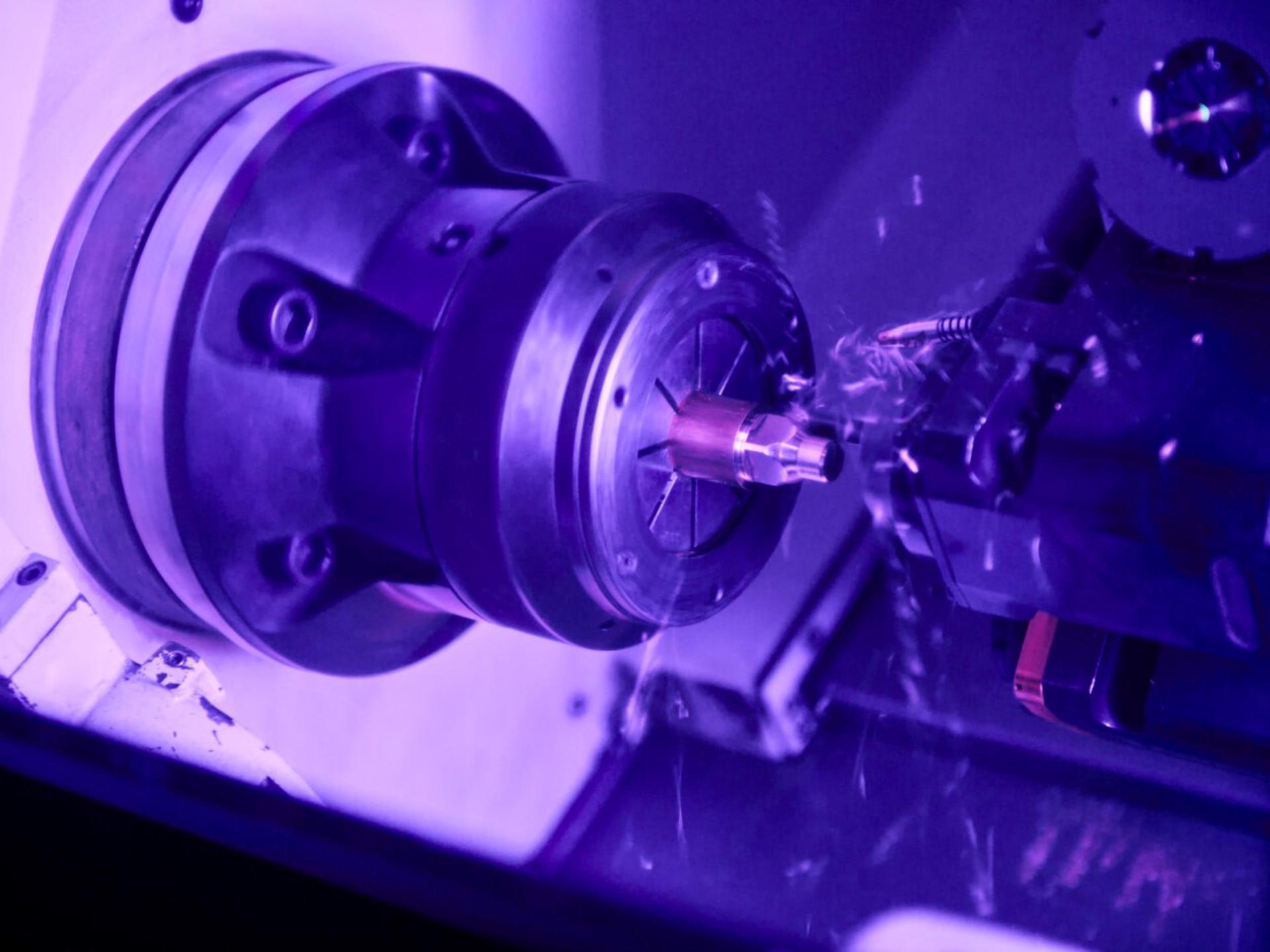

Computer Numerical Control (CNC) Machining

CNC machining is a subtractive manufacturing process where a computer numerically controls a range of tools including lathes, mills, EDM grinders, and multi-axis spindles to mill away excess material and manufacture parts out of metal or other materials.

-

Objet Printing

Objet Printing is a polyjet printing process that uses print-head technology to deposit photo-curable plastic resin, layer by layer.

-

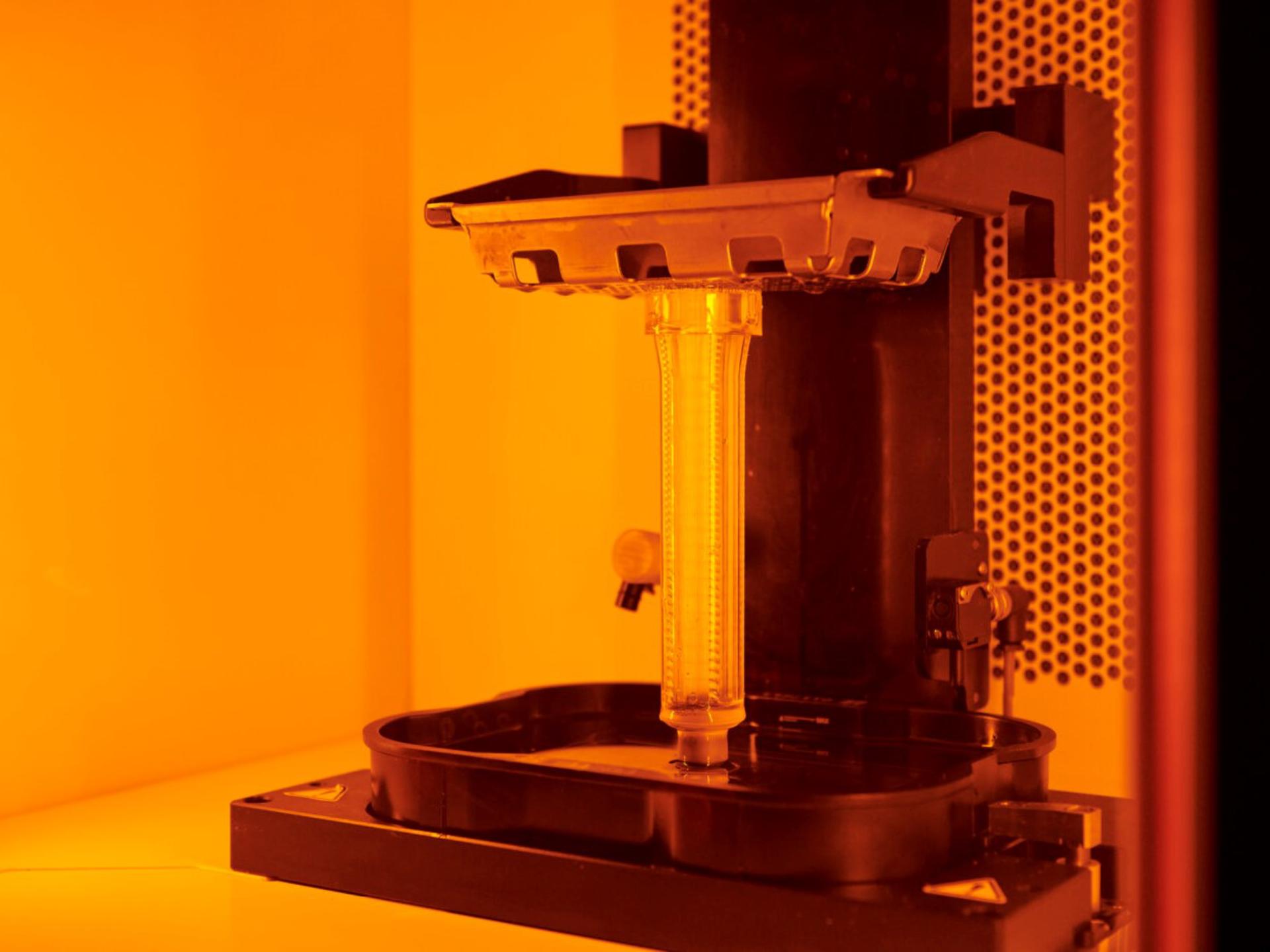

Figure 4

Delivers a fast additive manufacturing technology that is repeatable, has true-to-CAD part accuracy, fast, and offers a range of high-performance materials for prototyping, including medical grade and high temperature materials.

-

Stereolithography (SLA)

SLA converts liquid materials and composites into solid cross-sections, layer by layer, using an ultraviolet laser.

-

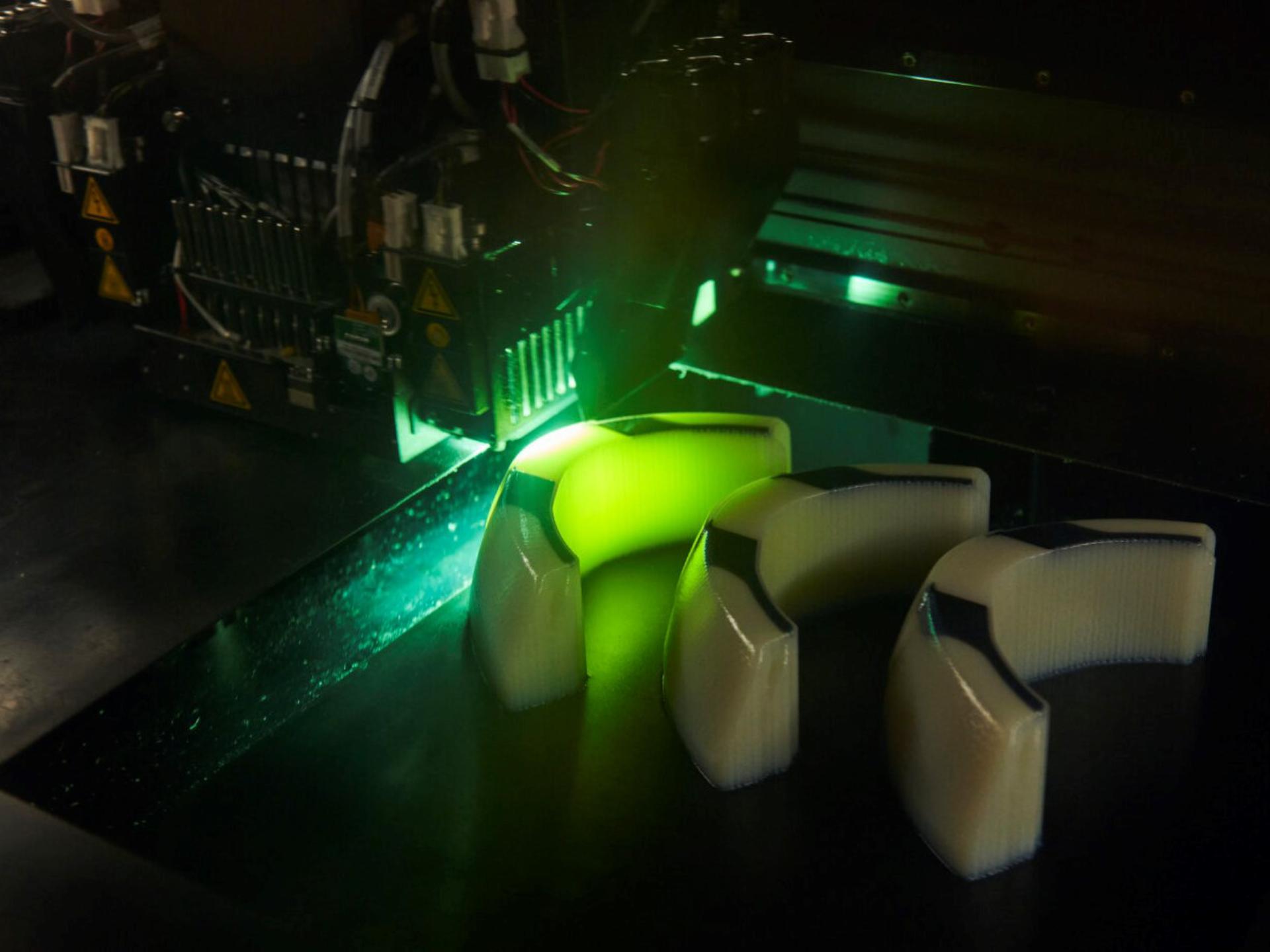

Selective Laser Sintering (SLS)

SLS technology uses a laser to harden and bond small grains of material, layer by layer, into a complete 3D structure.

-

Welding

Welding joins materials, usually metals or thermoplastics, by causing fusion. It can be done with heat and/or pressure and forms a joint that can be as strong as, or even stronger, than the base material.

-

Metrology

Metrology is the science of measurement. At Dyson, we have comprehensive Metrology labs across the UK and SEA with a variety of equipment for all measuring needs.